In accordance with the position of the gate and assembly program by client’s 2D and 3D, design reuse casting mold flow simulation software SOLIDCAST site casting speed and die in equal proportions into the case analysis of whether a lack of casting, casting shrinkage occur if no default, shrinkage and other adverse conditions to determine program

During melting pouring process, under the wax and liquid iron will pass under the iron and other processes at the state of contraction different body type has not seen the same situation

Depending on different types of casting, appropriate design of draw of pattern for operations that can speed up work efficiency and maintain the quality.

Making soluble wax mold is a likely situation if the internal shape is complex and it is difficult situation to draw of pattern while lost wax casting. The advantage for soluble wax mold is internal dimensionally stable and good roughness.

The data is going to be sent to CNC processing plant to machine mold after finishing taking apart the mold design.

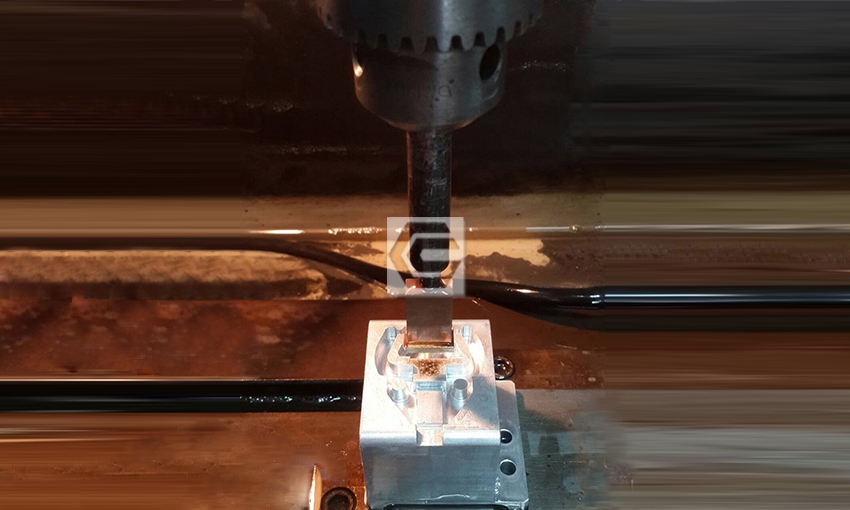

When CNC machining cutting tool face radius is too small or deep hole to machine. The choice is to use electrical discharge machining method.

When the mold returns from CNC processing plant, it needs to be done location and permeability assembly work.

Cleaning wax mold and testing to check for burrs and dimensional inspection.

Wax is injected into the mold. The time, pressure and temperature are controlled under SOP process in order to ensure the stability of the standard size.

When the mold using longer produces too much burrs and shell mold line, it need to rely on repair personnel to remove and repair and fix wax pieces flatness.

According to the proposal for assembling, wax and die head will be fabricated and send onto the conveyor belt to the next process.

The use of citric acid cleaning wax tree oil and release agent for about 30 seconds. To ensure the wax tree is clean before dipping.

The use of binder and refractoriness to make slurry liquid and mix with zircon sand and mulgrain sand are sequentially attached to a wax tree after repeating many times. It isn’t allowed any residual air bubbles until a predetermined thickness. The number of times and thickness of the ceramic shell are determined by casting weight. When small fonts and generally easy to ignore the gap on the casting, it can use vacuum dipping machine to solve the bubble problem.

Each layer requires some time to make dry in order to reach the strength. The drying room needs to maintain a stable temperature and humidity.

Put assembly wax tree into the high pressure container and locking through the steam-heated to make rapidly melt of wax outflow. The operation needs to be fast in order to prevent break and deformation.