The inspectors check casting appearance to classify casting quality with good quality, welding repair and rejection.

Caliper is used common dimensional inspection for basic measurement requirement.

High Gage is the main measure the height of object.

Placed a casting on the platform suitable for use in an optical projection irregular curve.

The use of detector to knock against casting surface and get the location coordinates. It suitable for more complex measurements or geometric tolerances.

We can make gages or round rod gages and get quickly test according to customer’s demand.

In accordance with customer needs to do different ways of casting hardness of heat treatment can be measured Rockwell hardness HRC and HRB.

In accordance with customer demand, we can make a specimen and viewed with a microscope. We can provide metallurgical report as well.

We can provide test report to check the inner hole of casting.

We can make simple gage to test the pressure of leakage test.

Magnetic particle inspection can be done to determine any tiny marks on the casting surface.

Make a tensile bar and do tensile test.

Each furnace sample is detected by the spectrometer and kept it more than a year. We can provide material certification to customers.

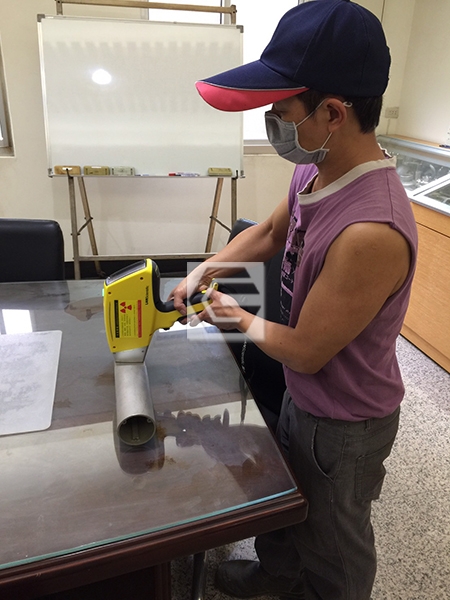

Non-destructive Test “ TrueX Handheld Alloy Analyzer” can judge material without damage any castings, which is conducive to product development and inspection.

Carton generally dominated by cardboard boxes that can be thicker layers in order to reduce impact injury in accordance with article.

Customized LOGO Special Box.

Use plastic bags or bubble bags by casting size or customer demand.

We can provide clamshell, rubber seal and PV cap etc.